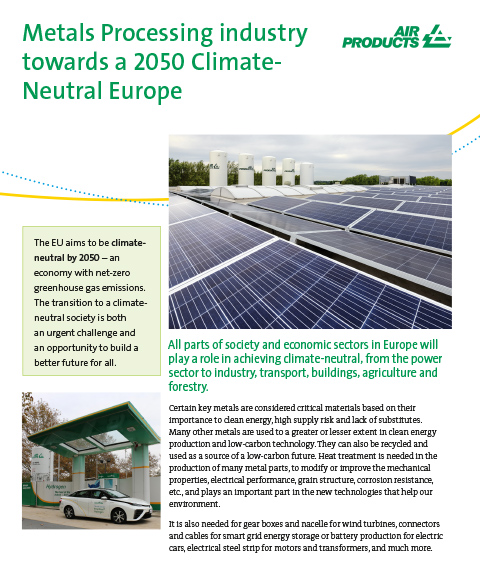

At Air Products we have developed heat treatment technologies than can help you to optimise your heat treatment processes, while ensuring the transition to climate-neutral with net-zero greenhouse gas emissions.

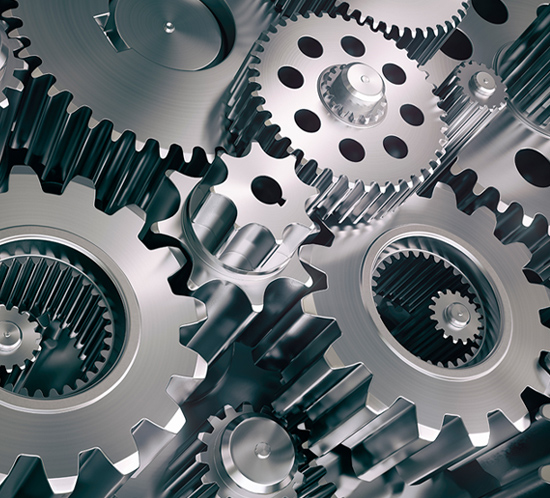

Heat treatment is needed in the production of many metal parts, to modify or improve the mechanical properties, electrical performance, grain structure, corrosion resistance, etc., and plays an important part in the new technologies that help our environment.

Contact us today

Our team of specialists can help you monitor, acquire and store your data.

0800 389 0202, or +44 1270 612708 (from outside the UK) or email apukinfo@airproducts.co.uk

Adviser service and consultancy for the heat treatment industry

Do you know…

... the structure of your production costs?

... what impacts your part quality?

... the CO2 footprint of your process?

… the bottlenecks in your heat treatment operation?

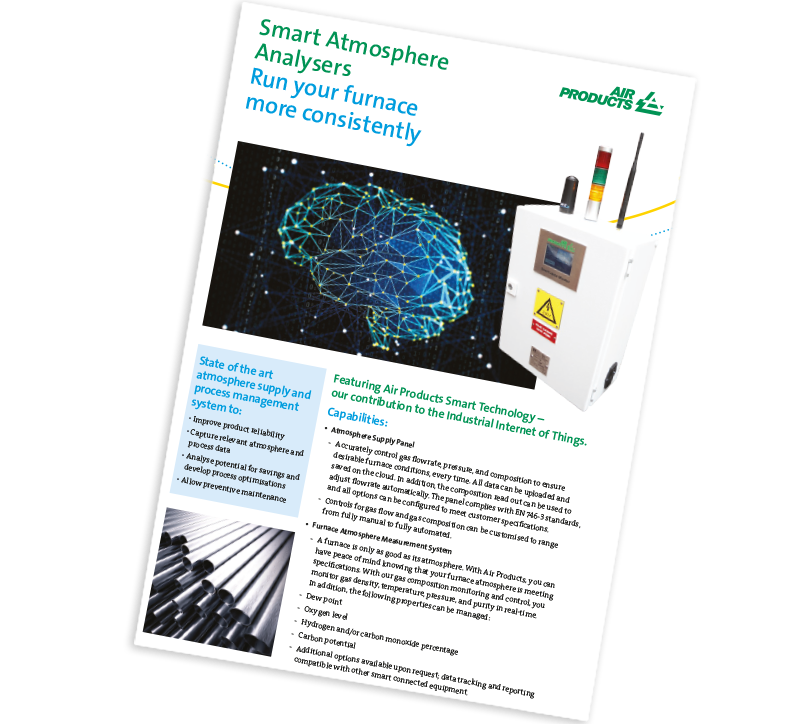

At Air Products we have developed smart features and cloud-based tools to help you to understand your process in more detail. You can optimise your operations by running more consistently with Air Products' Smart Atmosphere Analyzers and supply and process management systems.

Atmosphere optimisation and cloud based advisor services

Download PDF →

Improves product reliability

Captures relevant atmosphere and process data

Analyses potential for savings through optimisations

Provides alerts to conduct preventive maintenance

Enables compliance with CQI-9 and NADCAP requirements

Improves operator experience

Want to know more about our heat-treating solutions?

- Flexible protective gas atmosphere for carburizing and neutral hardening

Nitrogen, methanol and a small amount of a hydrocarbon gas are mixed in the furnace to a reaction atmosphere which corresponds essentially to that of an endogen during carburizing, carbonitriding and hardening.

tell me more →

- Protective gases atmospheres for annealing and normalising processes of ferrous and non-ferrous metals

For almost all annealing processes, we offer inert gas atmospheres based on inert nitrogen in combination with controlled amounts of hydrogen, methanol or hydrocarbons.

tell me more →

Download PDF →

Download PDF →