As an abundant, non-conductive and chemically inert gas, nitrogen is the atmosphere of choice for printed circuit board soldering applications. In this article, we look at how nitrogen can improve productivity, reduce defects, and maximize cost-efficiency in printed circuit board manufacturing.

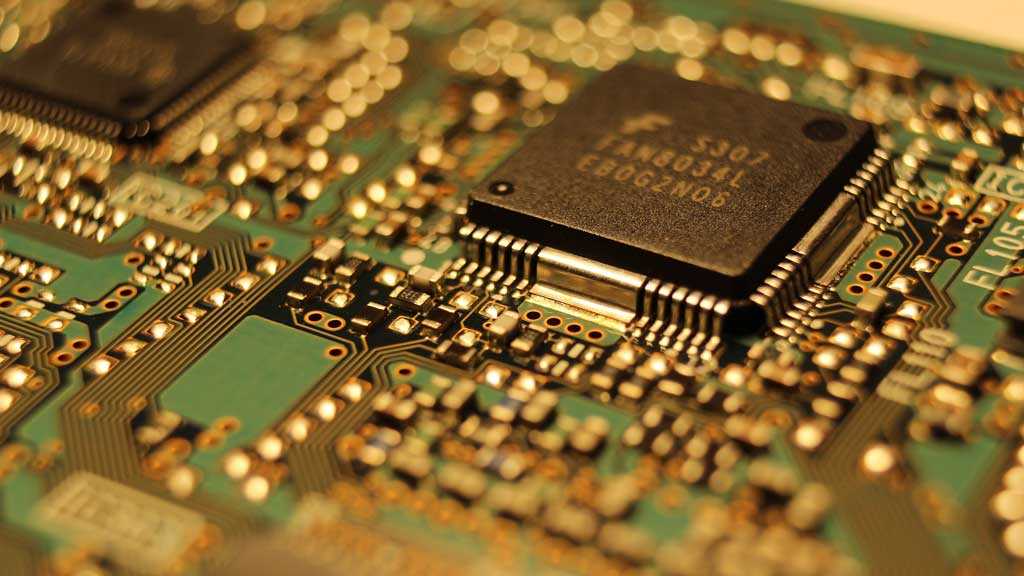

Found in virtually all electronic equipment, printed circuit boards (PCBs) have become the building blocks of modern electronics. The size of the global printed circuit board market is still growing – it was estimated at $12.1 billion in 2020, and is forecast to reach a size of $20.3 billion by 2026.1

PCBs consist of laminated insulating and conducting layers, with electronic components affixed to the surface. While the insulating layers form the bulk of the circuit board, conducting layers are etched into carefully designed tracks. Electronic components are then soldered to these tracks in predefined positions to form functional circuity.

PCB assembly – the process of depositing and soldering components to the laminated substrate – is typically carried out either by “through-hole technology”, in which component electrodes are inserted into holes; or by “surface mount technology”, in which components are placed on top of the PCB and held in place temporarily by solder paste.

This is then followed by soldering. Soldering can be carried out in a number of different ways, with bulk wave and reflow approaches being the most common.

During soldering, a controlled atmosphere is essential. Any reactive gases – such as oxygen and water vapour – can interfere with the solder joints, resulting in rejects.

Benefits of Nitrogen in PCB Assembly

The globally accepted solution to these problems is to use nitrogen as an inert atmosphere during electronics assembly. Compared to ordinary air, pure nitrogen is dry, inert and electrically non-conductive. Nitrogen also makes up the greater fraction (78%) of our atmosphere, making it far more cost-effective than other inert gases.2

An inert nitrogen atmosphere improves the wetting of solder, extending flux activity and reducing oxidation of the solder paste to produce higher-quality solder joints. In addition, using an inert atmosphere reduces flux residue and decreases the required process temperatures.3,4

The required purity of nitrogen depends on the process demands. As the complexity of printed circuit boards continues to increase, it is now more important than ever that soldering processes are reliable and defect-free. Using high-purity nitrogen is an easy way of ensuring good results: by minimising levels of impurities, unwanted contamination of solder joints is eliminated.

Air Products provides several grades of nitrogen gas suitable for PCB assembly. Ultra-high-purity nitrogen ensures better quality solder joints, fewer rejects, and less costly manual re-working of PCBs.

Nitrogen from Air Products is available in packs and cylinders for small-to-medium users; or, for medium-to-large applications, our CryoEase® service provides an easy and compact solution with minimal commitment and low investment. For larger-scale users, we also provide nitrogen in bulk, either in cryogenic tanks or high-pressure gas cylinders; and we’re experienced in delivering on-site nitrogen generation solutions.

To find out more about our nitrogen products and services for PCB manufacturing, get in touch with a member of the Air Products team today.

References and Further Reading

- Technavio. Printed Circuit Board (PCB) Market Size to Grow by USD 12.86 Bn | Rising Adoption Of Smartphones to Boost Market Growth | 17,000+ Technavio Research Reports. [https://www.prnewswire.com/news-releases/printed-circuit-board-pcb-market-size-to-grow-by-usd-12-86-bn--rising-adoption-of-smartphones-to-boost-market-growth--17-000-technavio-research-reports-301434184.html].

- Laboratory, S. U. H. I. on E. C. A. A. F.-P. S. B. A. B., NASA’s Jet Propulsion. The Atmosphere: Getting a Handle on Carbon Dioxide. Climate Change: Vital Signs of the Planet [https://climate.nasa.gov/news/2915/the-atmosphere-getting-a-handle-on-carbon-dioxide].

- Dong, M., Wang, Y., Cai, J., Feng, T. & Pu, Y. Effects of nitrogen on wettability and reliability of lead-free solder in reflow soldering. (2009) doi:10.1109/ICEPT.2009.5270776.

- Arslanian, G., Lin, M. & Wressel, A. Effects of Solder Reflow Conditions on the Assembly of Electronics Packaging and Printed Circuit Boards. [https://www.airproducts.co.uk/-/media/airproducts/files/en/450/450_11_001_glb-effects-of-solder-reflow-conditions-elec-packaging-printed-circuit-boards.pdf].