To find out which of our competitive welding solutions is right for your needs simply select your welding material type from the options below.

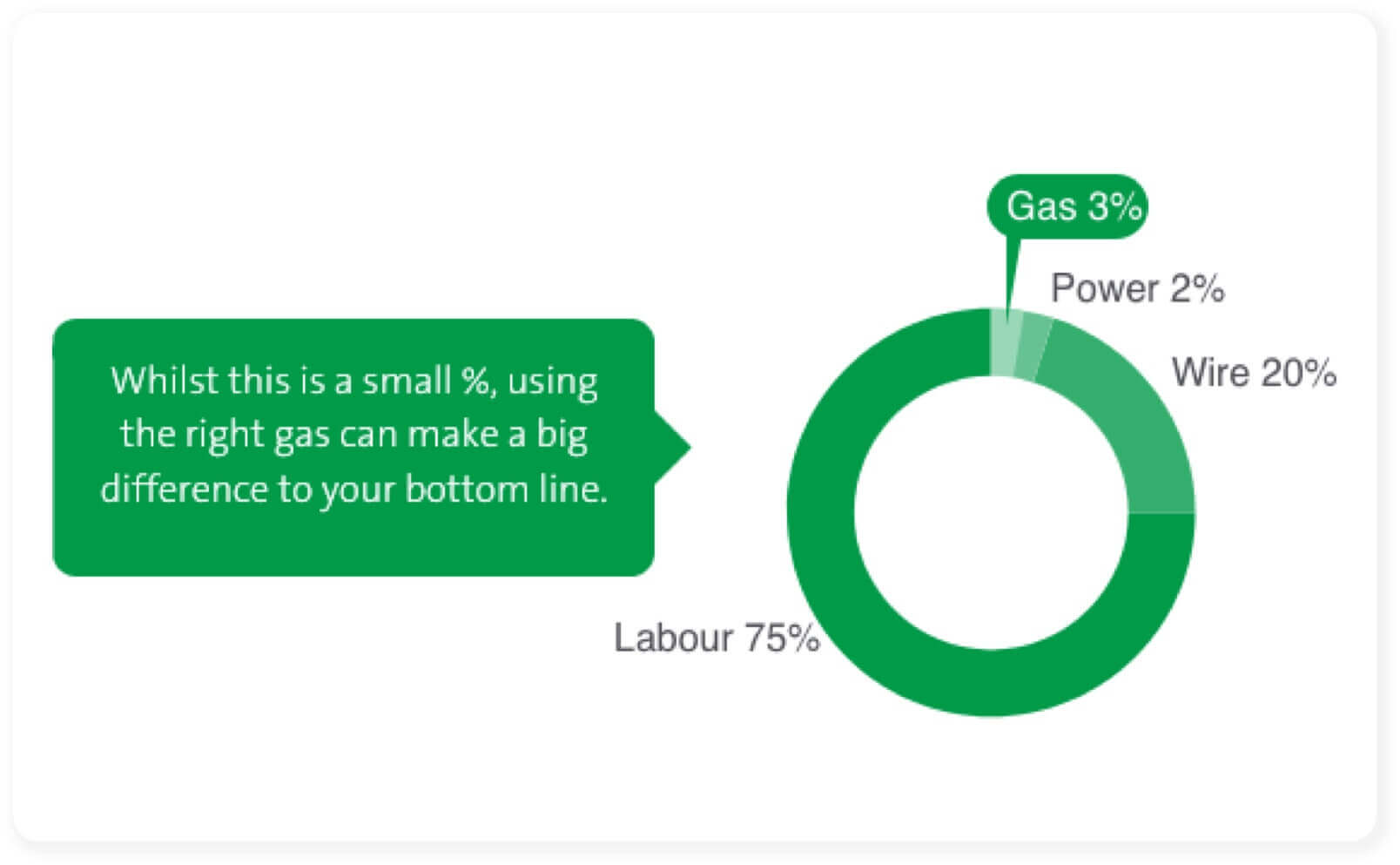

Welding gas only makes up 3% of the overall welding cost so is not a big decision, right? Wrong! Choosing the optimal gas for your set-up should bring multiple benefits for your business.

There are 9 key areas of your operation where Maxx® gas can have a positive impact. Contact us to see where we can generate savings for you.

Purpose designed for MAG welding carbon, carbon manganese and low alloy steels, the Ferromaxx® gases give superb weld quality and excellent penetration together with minimal spatter and low fume levels.

The Inomaxx® range of gases has been developed to give high quality welds in stainless steel which have excellent surface finish and superb corrosion resistance.

Alumaxx® Plus weld process gas has been specifically designed as the only gas that you need for the high quality welding of aluminium.

An industry leading comprehensive guide to gas shielded arc welding and oxy-fuel cutting.