Alumaxx®

One gas that does it all for aluminium

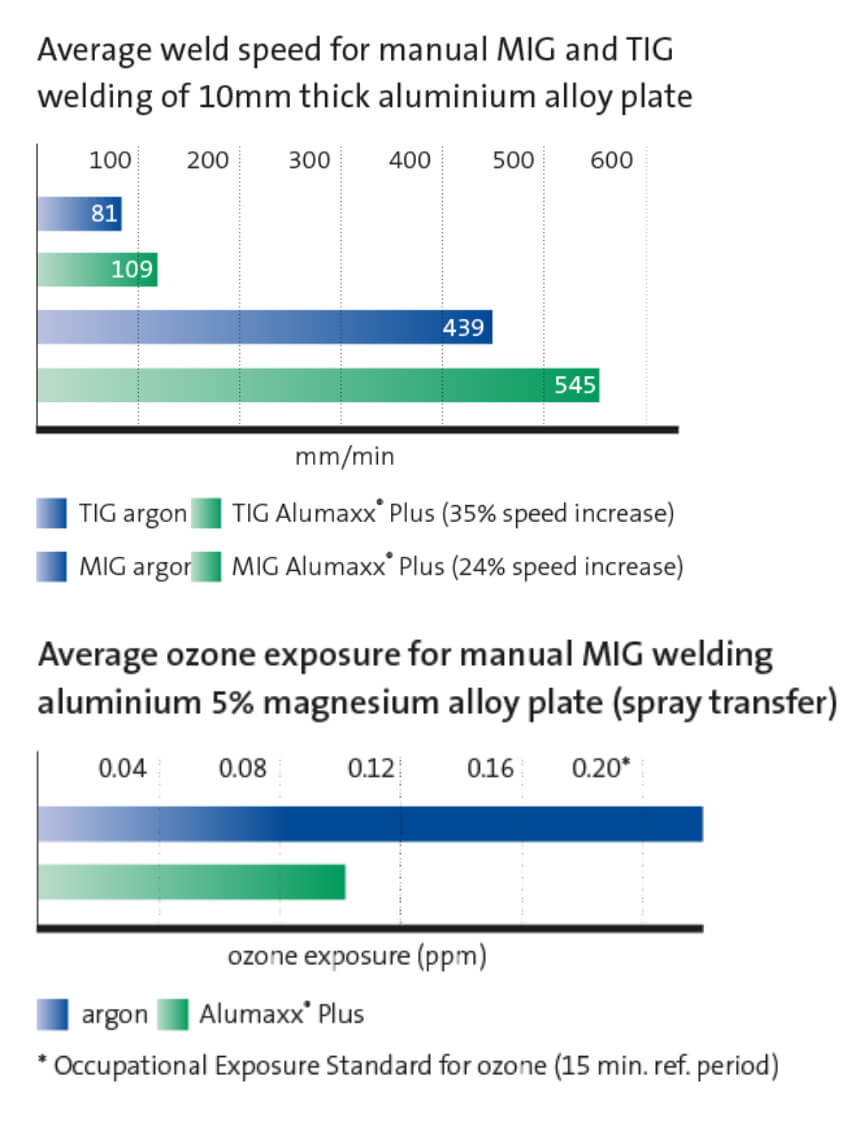

Alumaxx® Plus weld process gas has been specifically designed as the only gas that you need for the high-quality welding of aluminium and its alloys. If you aim for the most exacting standards, you'll need a dedicated gas like Alumaxx® Plus. A multipurpose welding gas, it is specially designed for MIG and TIG welding aluminium and its alloys across all material thickness.

Place An Order Book A Demo