Is your lab as safe as it should be?

Health & Safety

About the author

Stephen Robinson works at Air Products as BioMedical Product Manager. His background in chemistry led to a 27-year career at ICI, followed by time at Brenntag focusing on chemicals and gases. After 17 years with Air Products, he’s now a leading authority on cryogenic gases and equipment.

It goes without saying that caring for your team’s safety results in a whole range of benefits. Employees will think more highly of you; and fostering a well-managed safety culture gives staff more confidence, improving productivity and motivation, whilst lowering absenteeism and down-time. Reducing risks also reduces costs, with fewer accidents, lower staff turnover and a diminished threat of legal action. And outside your organisation, a good safety culture improves your reputation and standing among suppliers, partners and investors.

In other articles I’ve already talked about efficiency and sample security – both of which are an essential requirement in any cryo-lab – but safety has to be top of your list. If it’s not, you’re putting colleagues, samples, and even your operation at risk.

How safety can easily be overlooked.

Let’s be clear. I’m not saying anyone deliberately ignores safety rules in cryo-lab installations, but what I frequently find are disjointed set-ups, poor ergonomics, short cuts, inadequate training and doing the minimum to meet the regulations. That means those labs are taking big risks, often without realising. So how can that happen?

Procurement may be the problem.

It may be down to the way procurement has been carried out. For example, if one company has provided the freezers, another the gas and another the pipework, each supplier only takes responsibility for their part of the installation rather than the whole, leaving safety ‘gaps’. At Air Products, we always review the entire installation, whatever we’re providing.

Follow the right regulations.

Another example is down to different regulations. For instance, I’ve found some equipment suppliers don’t realise that standards applied in other countries don’t necessarily meet UK regulations. Therefore, purchasers and users of equipment don’t realise they’re not following the right regulations either. In such cases, I’ve had to advise customers on what they need to do to comply with safety regulations. We’ll always try to find a solution to allow customers to use their equipment, but there is the odd occasion where we are unable to supply gas as it cannot be done in a safe way.

The regulations are also constantly changing. What was good practice 10 years ago may no longer be so, and if any part of an older installation is changed then we are required to review the entire system against the latest regulations and advise the customer on what’s needed to meet them.

Complying with Codes.

The British Compressed Gases Association (BCGA) is the body that produces the Codes of Practice for the installation and use of various gases in cryo-labs. These provide guidance and recommendations on safe and effective practices relating to compressed gases; and as a member, Air Products would always ensure all relevant statutory regulations are applied in designs and installations covered by the BCGA Codes. Labs are also expected to carry out their own risk assessments to ensure that everything is in place for any visits by the mandatory bodies.

Things you can do to help, and how Air Products can assist

At Air Products, we always put safety first. It’s integral to everything we do. The industries we work in, supplying gases and equipment for a wide range of uses, often demand it. But we’ve always led the way in meeting and going beyond new safety regulations, setting and maintaining the highest standards. That’s especially important in any cryo-lab.

Helpful advice and guidance.

There’s plenty of other extremely useful guidance and advice available too. As part of our commitment to safety, Air Products’ extensive online resource includes a series of ‘Safetygrams’ – downloadable PDF documents covering many of the safety aspects of gases and related equipment. For cryogenic freezing, you’ll find numbers 7 (Liquid Nitrogen), 16 (Safe Handling of Cryogenic Liquids), 27 (Cryogenic Liquid Containers) and 49 (Safe Operation of Liquid Nitrogen Freezers for Cryogenic Freezing) most relevant.

Make sure staff are trained.

We also have a number of fully-accredited online training courses available covering gas safety, which can also be held on-site for group training. Training not only makes everyone more aware of potential issues, but more importantly makes sure your staff are up-to-date with all the current regulations to work in a safe and effective manner.

Putting the right safety culture in place.

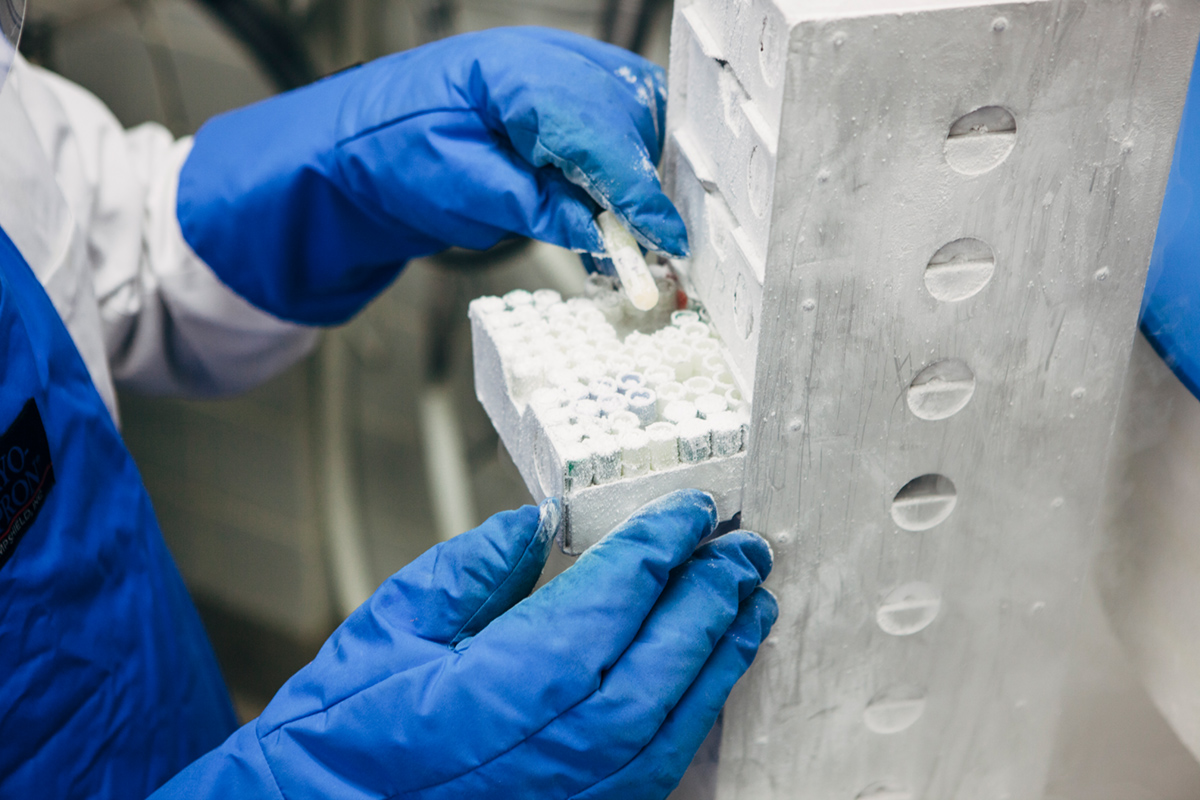

Under UK law, as an employer you have primary responsibility for the health, safety, and welfare of your employees and others affected by their work. Likewise, employees have a duty regarding their own safety and that of others. So whether yours is a small lab or a larger organisation such as a hospital or university, ultimately you could be liable if there’s a serious accident or incident. That’s why it’s crucial to avoid taking unnecessary risks every day by making sure your lab is set up in the safest way, and staff have the right training and PPE.

Put safety first.

Safety is an important element of any cryo-lab, and overlooking it can create a dangerous, even life-threatening situation. We believe mitigating risk is integral to running an efficient and secure lab, and our experts are always on-hand to help. We’ll look at your entire lab set-up, taking an overview to make sure every element is as it should be, so you have peace of mind that every aspect of safety is covered.

To find out more, simply talk to any of the Air Products team or book a free cryo-room audit.

Arrange to speak to

an expert

Complete the form below and one of our experts will be in touch.

Download our

brochure