How lab sustainability improves efficiency and reduces costs

Planning for lab sustainability

About the author

Jessica Davies works at Air Products as a Business Development Manager for the Speciality Gases & Life Sciences sector, covering the Yorkshire/Humber, East Midlands and East region of the UK.

Sustainability is a hot topic, and rightly so. It’s important for everyone’s future that we become more sustainable in many ways, and it’s an ethos that’s been ingrained at Air Products for decades. In a more immediate sense, if you’re planning, designing or managing a cryo-lab, sustainability is extremely important. So how and why should you make your lab more sustainable? And what benefits will it bring?

Sustainability and why it’s important in the lab.

The key benefit is that working more sustainably means improved efficiency. Whether upgrading older equipment or carrying out regular checks, these actions will reduce LN2 consumption, lower costs, speed up processes and improve sample security.

Additionally, if you’re looking for funding for improvement or expansion, a tangible commitment to sustainability may well need to be part of your business case. If you’re looking to partner with other organisations, many now insist on only working with those with a similar stance on their environmental impact.

If you’re linked to a University or the NHS for example, there are sustainability targets that need to be met (in the case of the NHS, it’s outlined in their sustainable supplier assessment). And inevitably, as environmental concerns continue to be an issue, regulations are likely to be introduced that will need to be complied with.

It begs the question, ‘why aren’t more research and lab facilities making these changes?’. Apart from a lack of awareness and a natural tendency to ‘stick with what you know’, the simple answer is the perceived initial outlay involved – but as I’ll demonstrate, being more sustainable doesn’t have to cost, and can save you thousands of pounds.

The right equipment.

As one of the UK’s major suppliers of both LN2 and cryogenic freezing equipment, we see the impact of poorly-designed rooms and the wrong choice of equipment every day. And having the right kit in place is possibly the most important step you can take; more sustainable equipment is easier to use, needs less energy and liquid nitrogen, offers greater sample security and is more cost-effective in the long term.

The key is to look at your total installation and make it as suitable as possible for your needs. Here’s an example: one client I was working with found their freezers needed more LN2 top-ups than previously, so their instinct was to look at installing a bigger external tank to hold more liquid nitrogen, taking up more space, incurring higher rental and costs and ultimately needing more LN2 deliveries. What we advised them to do was to be smarter at the other end – in other words, change their freezers so they used less LN2, could retain their existing tank, cut the number of deliveries and improve sample security.

Freezer upgrades

If you’re in the fortunate position of being able to specify or upgrade, there are many options available. These are from the MVE range, for example:

MVE HEco™ Series: High-efficiency, eco-friendly cryogenic freezers that provide vapour storage at -190°C. These freezers are designed for maximum storage density, sample security and reduced liquid nitrogen consumption.

MVE Vario™ Series: A popular alternative to Ultra Low Temperature (ULT) freezers, these can be used for cryo-storage and offer peace of mind with extended hold times of up to 96 hours. They provide consistent temperature profiles and significant cost savings compared with mechanical freezers.

When assessing freezers, it’s important to look at how much storage they offer and the amount of LN2 they use – after all, if you were buying a car, you might well judge it on the miles per gallon (or per charge, for electric vehicles), and the principle is the same with cryo-freezers.

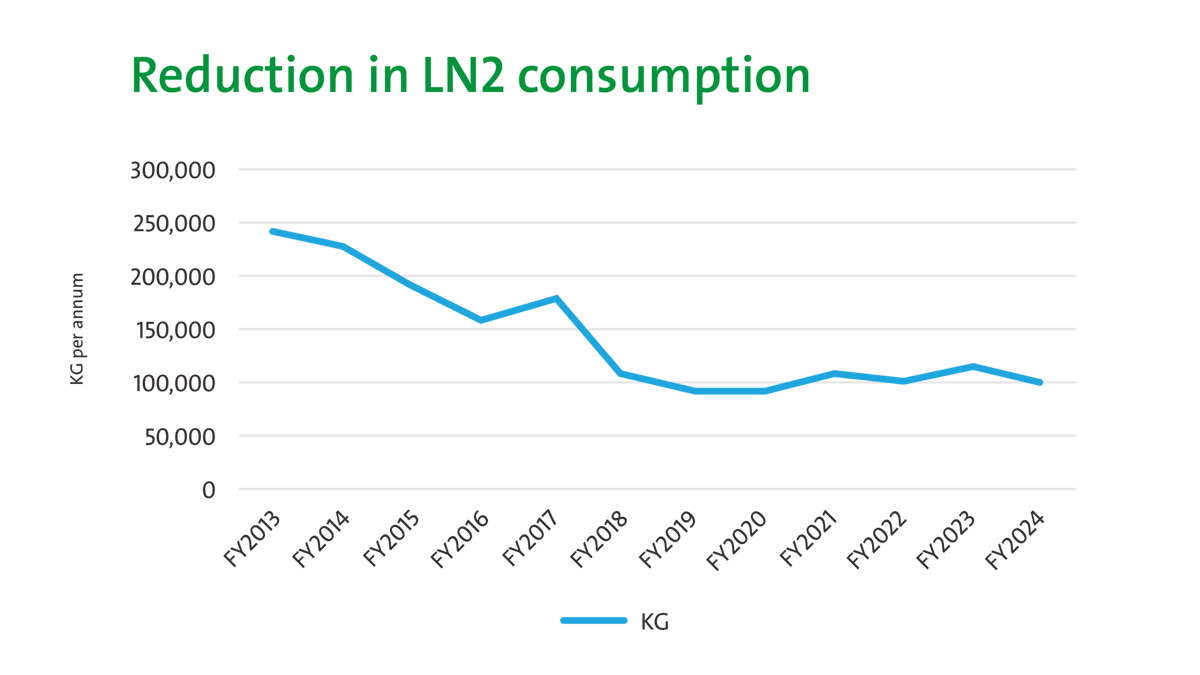

How much difference does switching to different freezers make?

This chart shows how one client, a national blood transfusion service, reduced their LN2 consumption by well over 50%. It also greatly reduced the number of deliveries they required to meet their needs.

Even if you’re unable to invest in new freezers right now, it’s important to plan ahead for when you are, and make sure the equipment you choose is right for you, reduces running costs and helps you meet any environmental regulations in the future.

Other measures

There are of course, other ways you can substantially reduce your LN2 consumption (and hence improve your sustainability) – such as changing your cryo-room layout or location to reduce the distance between freezers and LN2 storage, for example.

But if you’re not in a position to make those sorts of changes, there are still a number of other things you can do.

Small steps to sustainability

As with so many things, improved sustainability can come from the cumulative effect of a range of what appear to be small actions or details. Many of these are what we’d advise as best practice, and through regularly carrying these out you’d be surprised how much your LN2 consumption can be reduced, meaning fewer visits from our tankers and hence less fuel used in deliveries.

Here are just a few of the regular checks and actions you can carry out:

Check how well equipment is performing

It should be fairly easy to work out how much LN2 your equipment is using (if you’re struggling, talk to our team and they’ll help you).

Check seals and lids

If your freezers are using more LN2 than they should be, make sure the lids and seals are in good condition – worn seals and iced up lids are a common cause of LN2 evaporation.

Check hoses

If you use a braded hose to connect your freezers to your LN2 tank, check its condition; hoses tend to be under more stress than freezers due to temperature variations. If the hose needs replacing, consider a vacuum-insulated hose which offers consistent pressure and minimal liquid nitrogen losses.

Check SIVL lines

If you use an SIVL line, check that it’s working as it should – occasionally they need a ‘revac’ to restore the vacuum. You can easily tell if there’s a problem; if there’s condensation on the line, the vacuum’s not working properly.

Check LN2 tank and freezers

Similar to the SIVL line, if there’s frost on the outside of the tank there may be a problem with leakage. And if your LN2 freezers show frosting, they have likely lost vacuum.

Freezer filling

How you fill your freezers can greatly affect how much LN2 is wasted. If each is filled individually, your pipeline has to be cooled each time, using more LN2; the optimal method is to fill them all together in sequence (called the ‘daisychain’ method) so the pipeline only needs cooling once.

Manual decant

If your pipeline has a manual decant system to fill dewars with LN2, every time it’s used the line will need to be cooled. If it’s used frequently, a more economical (and sustainable) alternative is to fill a 50-litre dewar and decant from that rather than the pipeline.

Individually, none of these points may look as though they’ll make much difference; but together, and over time, they’ll all add up to substantial savings – and help you achieve your sustainability ambitions in the future.

In conclusion

While sustainability might not be a top priority for many labs and facilities, by following the steps we’ve outlined here – or better still, talking to an expert about your particular situation – It’s easy to make it integral to your cryo operation.

From reducing LN2 consumption to working more efficiently to meeting the latest regulations, there are both many advantages and substantial savings to be made by focusing on it. Even if you’re not able to invest in extensive changes now, it’s important to plan ahead in readiness. After all, the investment in sustainability will no doubt have to be made at some stage, and leaving planning too late can lead to poor decisions.

The team at Air Products is well-versed not only in the importance of sustainability and how to achieve it, but also in improving efficiency and supplying the very best equipment and gases (we’re the only UK manufacturer of MDR-certified liquid nitrogen), in terms of quality and safety.

If you’d like to talk to us about any aspect of your lab or biomed facility, we’ll be happy to help.

To find out more, simply talk to any of the Air Products team or book a free cryo-room audit.

Arrange to speak to

an expert

Complete the form below and one of our experts will be in touch.

Download our

brochure