Are your samples as safe as they could be?

Protecting Vital Samples: Why Sample Security is Key in Cryopreservation

About the author

Stephen Robinson works at Air Products as BioMedical Product Manager. His background in chemistry led to a 27-year career at ICI, followed by time at Brenntag focusing on chemicals and gases. After 17 years with Air Products, he’s now a leading authority on cryogenic gases and equipment.

A compressor fails. A sensor doesn’t trigger the alarm. Even just a simple power cut. For many labs or sample storage centres, it doesn’t bear thinking about – the nightmare scenario of vital samples ruined in just a matter of hours.

It’s all too easy to think ‘It won’t happen to me’ – but it can happen, even to the best. In 2012, the Harvard Brain Tissue Resource Center in Massachusetts lost 147 samples due to a freezer failure; in 2019, a Los Angeles hospital similarly lost 56 stem cell samples from child cancer patients; and in December 2023, Sweden’s Karolinska Institute lost decades-worth of research samples through a freezer malfunction.

Those are just a few examples of how things can go wrong very easily. But what many people in the lab sector don’t realise, is that there are solutions available that help to significantly mitigate the risks to greatly improve sample security.

The role of the lab freezer

At Air Products, we take the view that we don’t sell freezers – we sell insurance. And it’s true, nothing is more important to patients, medics or research teams (and, of course, to Air Products) than the security of vital samples. The lab freezers you use play a crucial role in that; but rather than simply opt for the same as you’ve always had, or what colleagues recommend, it’s worth considering several important factors – all of which can have an impact not only on the security of your samples, but also the efficiency, sustainability and running costs of your laboratory.

Mechanical vs cryogenic

For temperatures down to -20°C, mechanical freezers are very reliable and the least complex method. As low as -80°C, Ultra Low Temperature (ULT) mechanical freezers can be used, but become increasingly complex and less reliable. And if you need -135°C or lower, ULT freezers are highly complex and prone to failure, with Liquid Nitrogen storage proving the least complex and most reliable.

Rethinking your sample storage

Remember too, that when looking at the different options it’s important to view the bigger picture rather than just the temperature capabilities of different types of freezers.

In terms of infrastructure, with ULT storage you’ll need complex electrical distribution (high voltage, with emergency power generation possibly from a costly back-up generator which also needs regular maintenance), a highly enhanced HVAC system, back-up specimen storage (just in case) and highly-qualified service technicians. On the other hand, liquid nitrogen storage just needs standard electrics, low level room extraction rather than HVAC and can use battery back-up power. It does however need a liquid nitrogen supply (whether from dewars or a bulk pipeline) and oxygen depletion alarms.

The option we recommend

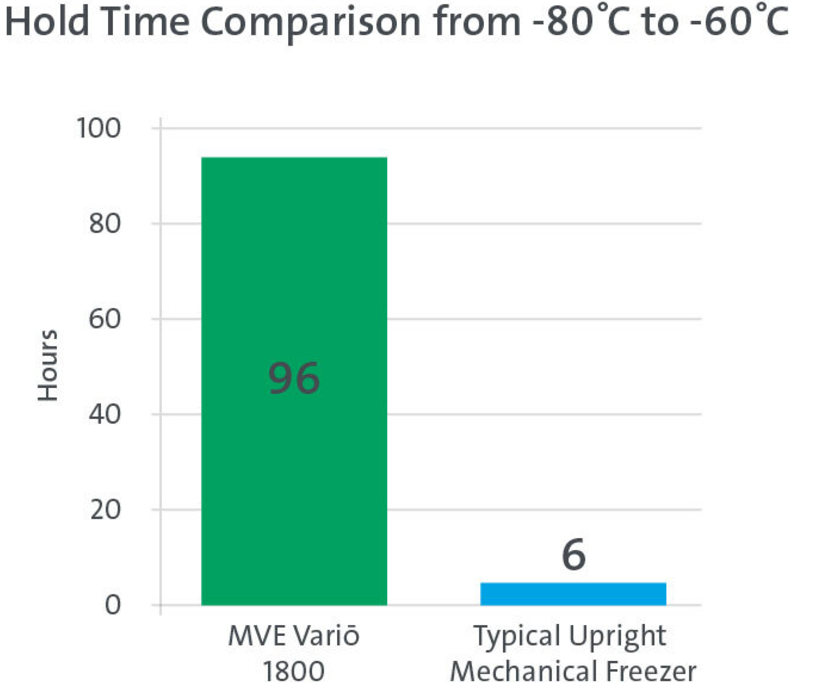

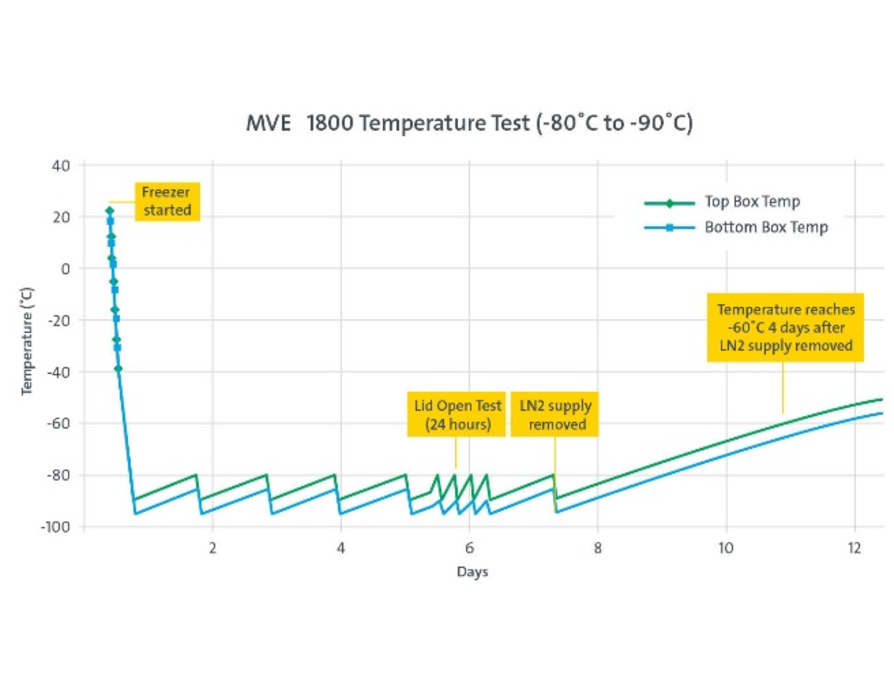

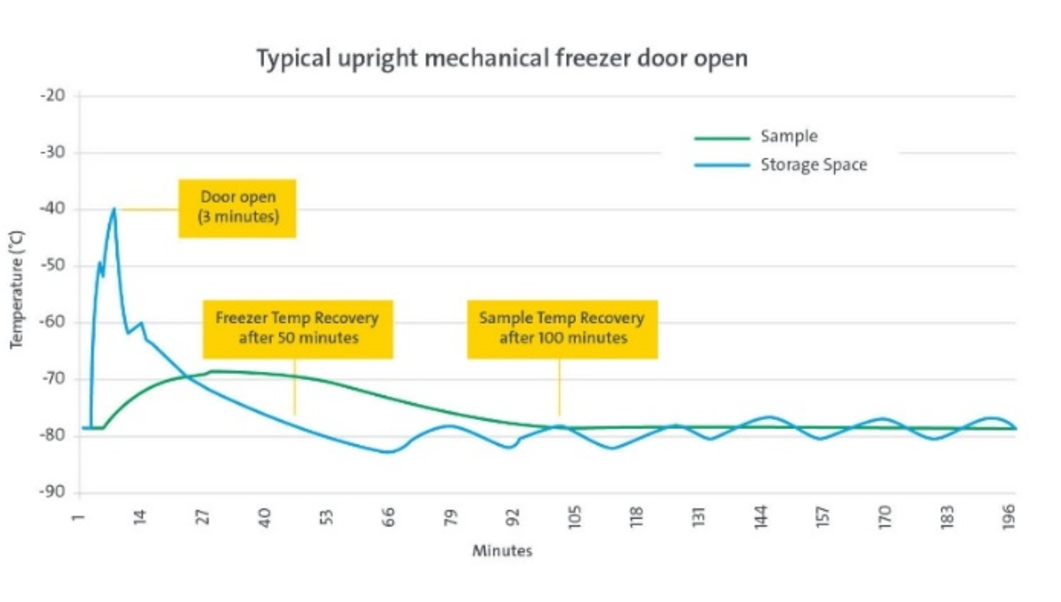

Many of you might well be used to (or already using) mechanical ULT freezers in your lab. But comparing the two, it’s clear that liquid nitrogen storage has several advantages over ULT. Its simplicity, with minimal moving parts, no compressors and no extra HVAC requirements, mean it’s a highly reliable system. And most importantly, its long freezer hold times – up to 96 hours, as opposed to just a few – increase safety margins, ensuring uninterrupted preservation and giving you much more time to respond if anything should go wrong.

If you do decide to opt for Liquid Nitrogen, the question then becomes which freezer you should choose. In our experience, we’ve found that MVE’s Variō series offers a host of benefits in addition to improved sample security – and it’s best suited to facilities with multiple freezers in one room (ideally on the ground floor next to an external wall.

The most energy-efficient ULT freezer available

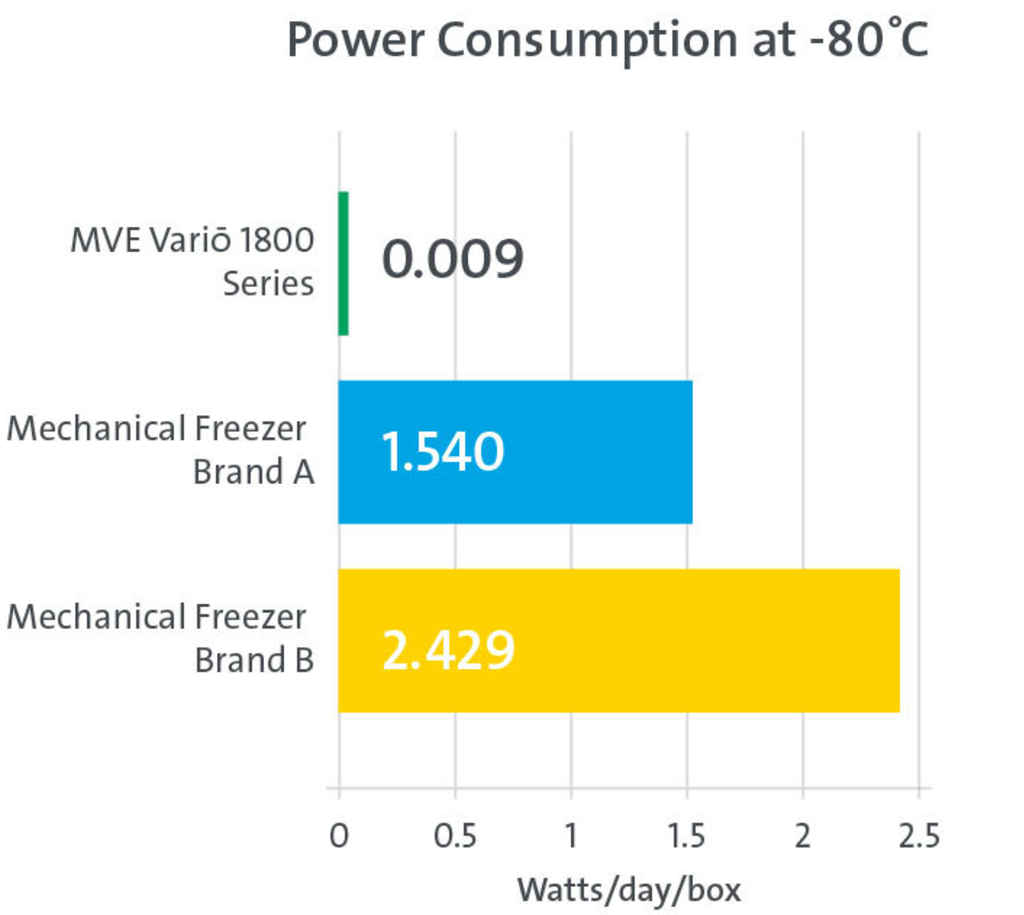

To begin with, it’s impressively energy efficient, using just 1% of the power needed by mechanical freezers, reducing your carbon footprint and leading to around a 70% saving in operating costs.

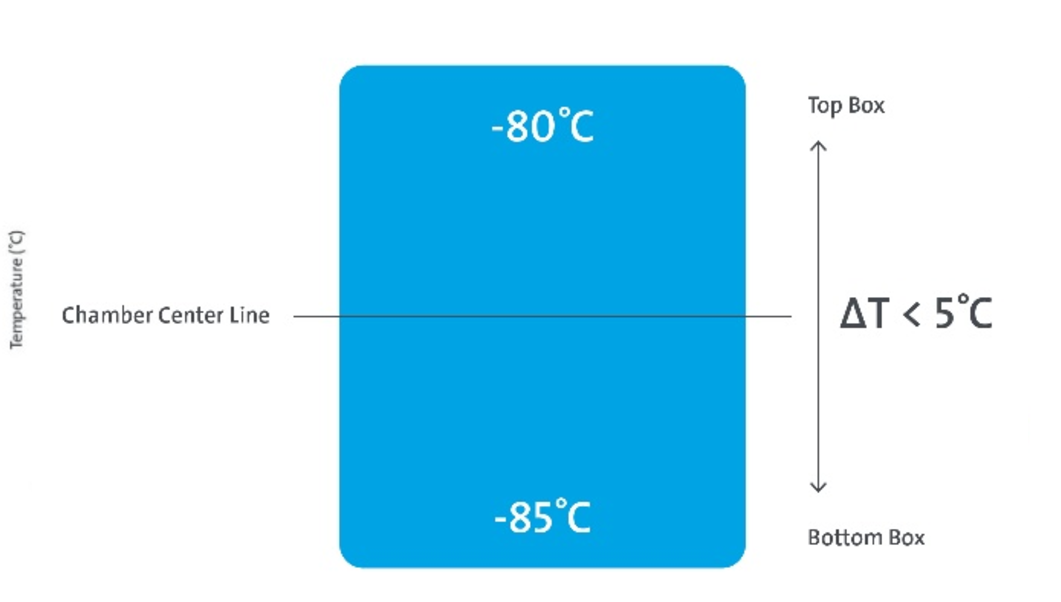

The Variō also offers an exceptionally uniform temperature profile giving consistent and stable condition throughout the freezer with no hot spots – even when the lid is opened, thanks to advanced insulation technology and rapid temperature recovery.

In addition, having liquid nitrogen in the freezer means samples are stored in an inert, dry atmosphere, with far less chance of icing compared with mechanical freezers.

Versatility, efficiency and capacity

Unlike mechanical freezers, the MVE Variō series is designed to operate anywhere between -20°C and -150°C, with a conversion kit available to turn it into a high-efficiency -190°C freezer. Such flexible temperature control, together with reduced energy consumption and no need for special HVAC systems, make it an extremely versatile and cost-effective solution.

In many cases, labs, clinics and biobanks, space is often limited – but Variō freezers offer significantly higher sample storage capacity per cubic metre compared with mechanical freezers, maximising storage efficiency with an innovative design that optimises internal storage configuration to store more samples in the same footprint.

In summary

It’s understandable why mechanical freezers have been the industry standard for so many years. But when you realise how many components have the potential for failure – not to mention the extra strain they put on HVAC and electrical systems – we’ve found that for sample security, they simply can’t match the simplicity and reliability of liquid nitrogen ULT freezers.

And when you look at the bigger picture and take into account lab efficiency, running costs, sustainability and storage space, for me choosing the right freezer option is simple.

Find out more about the Variō Series of LN2 freezers here.