Disaster prevention: why it’s critical in cryopreservation

Disaster prevention and recovery with power outages or equipment failure

About the author

Keith Lewis covers the West of England and Wales and with 39 years of expertise in the supply of Industrial and Speciality Gases you can be assured of expert help in your application.

Cryo-labs have a great deal of responsibility: safely storing samples on behalf of researchers, medical teams, IVF patients and more. In fiscal terms those samples can be worth millions, in emotional terms many are simply irreplaceable.

So for any lab manager, the idea that something out of your control that could destroy those samples simply doesn’t bear thinking about. An external power outage, a machine malfunction, an alarm failing, an issue with your LN2 supply…all have the potential to spoil the samples you hold. But that’s not all. In addition to the financial liability of losing valuable samples, the reputational cost could be catastrophic for your business.

Admittedly, complete failures are rare and therefore the possibility is often overlooked. But they do happen – and when they do, the consequences can be dire.

A perfect storm

As outlined in our previous blog on sample security, there have been several cases of circumstances coming together and samples being lost in recent years.

In late 2023, for example, a freezer malfunction caused the loss of decades of research – primarily into leukaemia – at the prestigious Karolinska Institute in Stockholm. In 2019 a Los Angeles hospital lost 56 stem cell samples from child cancer patients through freezer failure; in 2012 a man sued Edinburgh’s Western General Hospital over damaged sperm samples due to freezer problems; and two separate fertility clinics in Ohio and San Francisco were sued as a result of catastrophic cryostorage failures. And in this 2012 incident, a hospital in Rome lost 94 embryos when the liquid nitrogen ‘was no longer there’ – and while the hospital blamed their LN2 supplier, an alarm had signalled the rising temperature but no-one had heard it, as the alarm was in the basement and the lab on the floor above.

Examples like those prove the value of every lab having an emergency plan in place; in fact, it’s impossible to over-stress just how important it can be. This article, from the National Institute of Standards and Technology (NIST) in the US, is a good example of the sort of preparation undertaken by their cryogenic storage facilities in case of a power outage due to hurricanes.

Every lab is different though, with many variables, and preparing for every eventuality means carrying out an assessment specific to your particular circumstances. But where do you begin?

Fail to plan, plan to fail

The old adage was never truer – preparing for the worst possible scenario begins by thinking ahead. But ironically, in the case of cryogenic storage, it means literally planning tor failures that could happen at any time. What if the power fails? What if a freezer breaks down? What if there’s a problem with our liquid nitrogen line? Or what if there’s an issue along the LN2 supply chain?

Adopting a ‘what if’ mindset is where any emergency planning starts. Running through each possible issue helps to pinpoint where any weak points are, so measures can be put in place to maintain the integrity and continuity of your critical storage system, mitigating risks and ensuring regulatory compliance.

The Air Products Biomedical team often advises on where potential failure points lie and how to make cryogenic storage systems more robust; two of the most common vulnerabilities we come across concern power outages and equipment failure.

There are various possible solutions to both those potential issues. In the case of power failures, somewhere like a hospital or university may have a UPS (Unbreakable Power Supply) or emergency generators in place; some LN2 freezers also have a battery back-up in case of power outage. And in case of equipment failure, in organisations even have back-up freezers permanently on standby; but for many labs, these can prove not only inefficient, but unaffordable.

Time is your worst enemy

In the event of either failure, successful mitigation boils down to one thing: time, and how much of it you have before you reach a critical situation. Quite simply, the more time you have before your samples become critically warm the better the chances of their surviving unscathed.

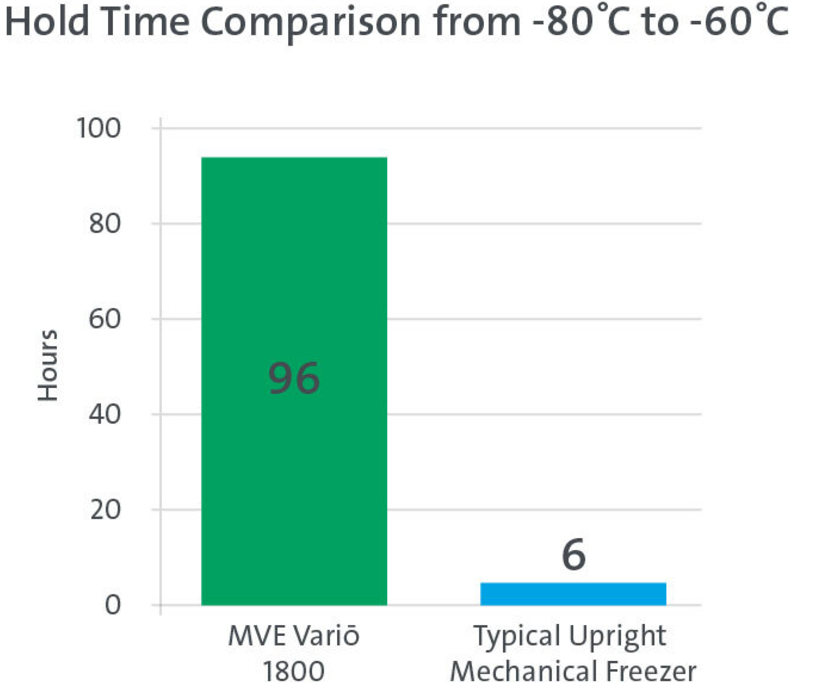

That’s why we focus on recommending measures that give you the most time to solve whatever problem has occurred – such as back-up power, alarm systems and remote monitoring that tells you the instant a failure occurs. It’s also the reason we frequently recommend High Efficiency LN2 freezers (such as those in the MVE range) over ULT freezers – while they have a hold time of up to 96 hours, depending on the model High Efficiency freezers can provide between 13 and 27 days’ hold time. Which greatly increases the safety margins and better ensures uninterrupted preservation (see below)

In summary

Just as it’s impossible to over-stress the importance of preparation, it’s impossible to foresee every eventuality that could have serious consequences for your operation. But that’s not a reason to ignore it; on the contrary, every lab should follow this simple checklist to make sure they do as much as possible to mitigate the risk of a serious incident.

- Carry out a comprehensive risk assessment – by identifying risks, measures can be put in place to prevent them

- Emergency planning – make sure you have a plan in place so everyone knows what to do in case of an emergency

- Rigorous training – if every member of staff knows what to do in case of emergency, it also helps make them more aware of avoiding dangers in the first place

- Regular equipment maintenance & safety checks – with so many of the most serious incidents being caused by equipment failures, draw up a strict schedule for maintenance and checks to ensure it’s always working as it should

- Alarms & Sensors – make sure you have the necessary alarms in place not just for fires, but also for LN2 leaks, temperature anomalies or freezer failure – and carry out regular checks that they’re working properly

This is just a basic checklist as a starting point – there are, of course, many other potential issues that could occur in any cryogenic storage facility. And the truth is you can never be too prepared.

The simple solution

As we’ve learnt over the years, every storage facility is unique. And few lab managers have the time or specialist knowledge to carry out assessments and implement the necessary measures in case of emergency. Which is why working with an experienced, trusted partner who can make sure you lab is robust enough to avoid potentially disastrous situations can prove invaluable.

The Air Products Biomedical team is always available to act as a long-term strategic partner, providing expert advice and guidance based on your current set-up, your needs, your location and your budget. If you’re at the point of upgrading or creating new facilities, we can help you make the right decisions for long-term sample security as well as ensuring scalability and sustainability for the future. And we can also advise on integrating new technologies into legacy infrastructures, balancing cost and risk regarding back-up systems and making sure the right emergency protocols and training are in place.

All of which is designed to help you decide on your priorities, make your facility as failsafe as possible and, ultimately, give you and your team comprehensive peace of mind.

Worried about sample safety in your lab? Contact the Air Products Biomedical team here.

Arrange to speak to

an expert

Complete the form below and one of our experts will be in touch.

Download our

brochure